Our Correct Strapping Diaries

Examine This Report about Strapping Tapes

Table of ContentsThe smart Trick of Pallet Strapping For Storage That Nobody is Discussing4 Simple Techniques For Strapping ToolsPlastic Strapping - Packaging Materials Fundamentals ExplainedSome Known Facts About Cargo Strapping.What Does Strapping Machine Do?The Only Guide for Shipping Strapping MaterialsGetting My Strapping Material To WorkRumored Buzz on Taping And Strapping SystemsThe 6-Second Trick For Correct Strapping

The material is simple to utilize due to the fact that of the adaptable nature of the straps. This strapping material works terrific for short periods however isn't advised for long-term storage.The fabric material is light, making it an efficient remedy for safeguarding fragile products. At the exact same time, the polyester is tear-resistant and also offers extreme strength for large, hefty tons. The downside to polyester is that it doesn't work great in automated equipments. These straps function most successfully when combined with hand tensioners.

How Quality Strapping Systems can Save You Time, Stress, and Money.

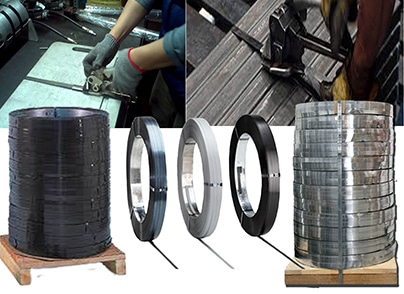

When you need to protect stiff and also heavy lots, metal provides among the toughest durability as well as efficiency choices. Steel bands are likewise recommended if the tons is company (does not compress) or if there are rough or sharp edges such as concrete, iron, or mass lumber. Metal bands aren't bendable, so you require to ensure the bands are sized to fit each load.

While steel is suggested for sturdy materials, it's as well rough if you are managing products that are quickly damaged. The expense of steel strapping can be high, so it might be out of your rate range if you have a tight spending plan. At Gertex Solutions, we offer full-service assistance to help you pick the ideal equipment for your business.

Everything about Types Of Plastic Straps

Our objective is to support your product packaging automation, which can improve efficiency and also conserve you cash. What concerns do you have about strapping equipments? If you would certainly such as even more details about the right devices for your organization, after that contact us to arrange a free assessment (flejadoras).

Strapping is one of the most typically utilized method to bundle products for shipping. There are numerous various sorts of strapping available and it is very important to recognize the specs and make use of for each and every. An usual misconception is that plastic strapping is all the very same, yet there are extensive distinctions between the 2 major materials, polyester (PET) as well as polypropylene (poly).

Not known Facts About Shipping Strapping

Polypropylene strapping has a matte finish and is normally embossed. Polyester keeps stress over an extended period of time. Polypropylene has actually low retained tension, frequently losing concerning half of the used tension with a hr of being applied. This loss can be accelerated by particular environmental elements as well. Polyester can be used by handbook devices, battery-operated strapping devices, and also fully automated devices.

is the much more inflexible and also solid alternative. Often used as a replacement to steel strapping in many sectors. It's made use of in durable packing applications such as delivering bricks, steels, drink pallets, as well as various other heavyweight packages. It's the preferred option in situations where you require a greater preliminary as well as maintained tension with much less prolongation, which enables it to hold a load effectively for longer durations of time.

Our Pallet Strapping PDFs

When individuals use the term 'poly strapping', they are most likely referring to polypropylene. It's usually used to unitize food products, timber, and also plans of a lighter weight.

The smooth finish has no extra coating so the strapping slides easily through strapping devices when being used. You also require to analyze your existing strapping tools. There are no devices that cover every band dimension or kind. Some tools and also machines can be utilized with any type of sort of plastic strapping as well as some can just be used with either polyester or polypropylene.

3 Easy Facts About Plastic Strapping & Seals Shown

Such as, which kind of strapping is recommended for my product? When to make use of straight and/or vertical strapping? What strapping accessories can be consisted of?

The vertical strapping system links the goods to click reference the pallet base vertically utilizing the strap. The 2 systems are not replaces for each various other, but instead one system or the other is advised depending on the lots securing and make-up objectives (security or frailty of the product, kind of main product packaging, kind of palletizing, previous protecting, etc). emplaye. Playo.

The vertical strapping system links the goods to click reference the pallet base vertically utilizing the strap. The 2 systems are not replaces for each various other, but instead one system or the other is advised depending on the lots securing and make-up objectives (security or frailty of the product, kind of main product packaging, kind of palletizing, previous protecting, etc). emplaye. Playo.How Polypropylene Plastic Strapping can Save You Time, Stress, and Money.

On the other hand, with hefty lots that need to be linked and repaired to each various other, at the threat of falling or moving, horizontal strapping is generally used to portable them as a block. To find out more on the differences between both types of strapping, we recommend our strapping contrast: Read this story on Pallet strapping: Contrast between vertical and straight strapping systems Automatic Vertical Strapping System and also Horizontal Strapping System in an Automatic Packaging Line Strapping of plans, boxes, and also pallets can be finished with guidebook, semi-automatic, and automated devices, although for pallets it is constantly suggested to use automated pallet strapper for security as well as optimization factors.

These are mobile, robot-type machines used to strap pallets with the intervention of a driver to area and get the strap. Semi-automatic strapping equipments have the advantage of being compact and also versatile as well as offer a much better hold than hands-on devices for small product packaging demands, in a stockroom or logistics location without an end of palletizing line.

Plastic Strapping - Polypropylene & Polyester Coils Things To Know Before You Get This

Improving the stability of tons during transportation is one of one of the most desired purposes in a product packaging system. And certainly among the most favored systems for securing is strapping systems. Questions commonly develop concerning the specs and also wide range of strapping alternatives that exist in the market today. flejes. Such as, which kind of strapping is advised for my item? When to make use of horizontal and/or upright strapping? What strapping devices can be included? In this article, following our TOP 10 FAQ collection, we address the most frequently asked inquiries navigate to this web-site we receive concerning pallet strapping systems.

The vertical strapping system ties the goods to the pallet base up and down utilizing the strap. The two systems are not replaces for each other, however instead one system or the other is recommended depending on the lots protecting and composition goals (security or frailty of the product, kind of primary packaging, kind of palletizing, previous safeguarding, etc).

The vertical strapping system ties the goods to the pallet base up and down utilizing the strap. The two systems are not replaces for each other, however instead one system or the other is recommended depending on the lots protecting and composition goals (security or frailty of the product, kind of primary packaging, kind of palletizing, previous safeguarding, etc).4 Simple Techniques For Strapping Tools

On the various other hand, with hefty lots that need to be linked as well as taken care of to each various other, at the danger of falling or shifting, straight strapping is typically used to compact them as a block.

These are mobile, robot-type devices used to band pallets with the treatment of an operator to area as well as grab the strap. Semi-automatic strapping machines have the benefit of being small and also versatile and also offer a much better grasp than hands-on equipment for tiny product packaging needs, in a warehouse or logistics location without an end of palletizing line.